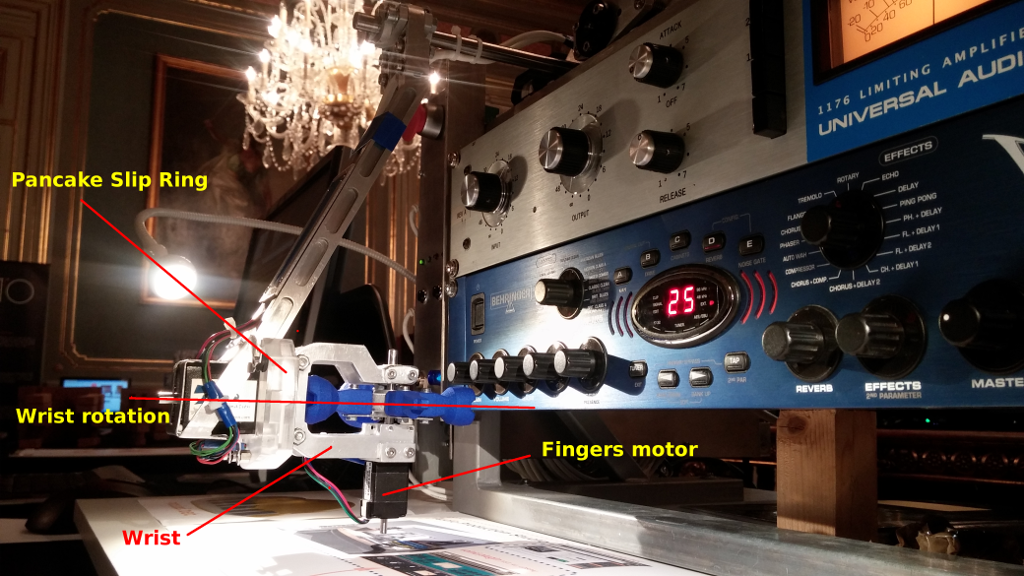

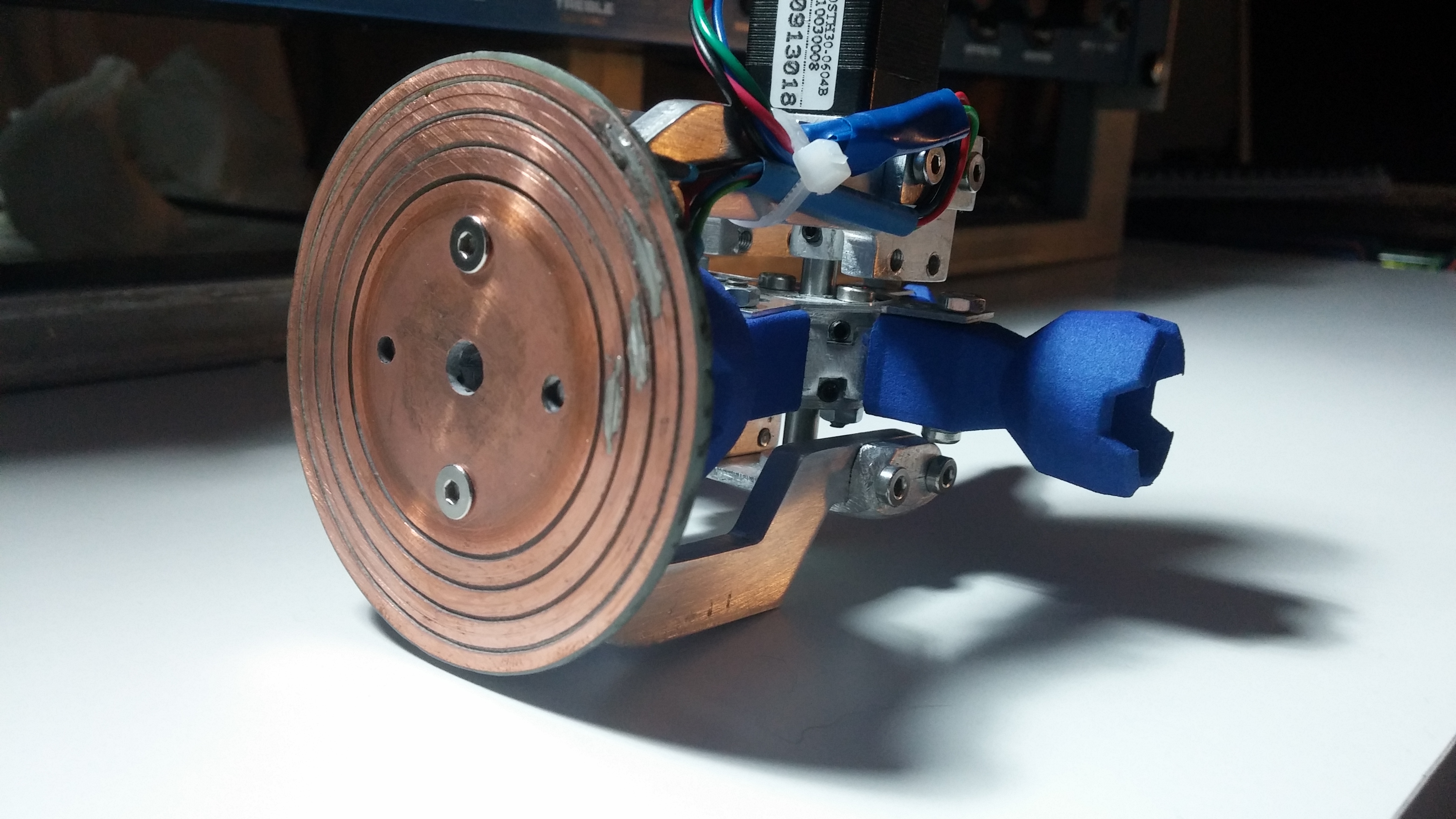

The end effector for the voind robot consists of a “hand” with selectable “fingers” rotating over a “wrist” capable of rotations in excess of 360 degrees. To bridge this rotational gap and transport the 4 signals needed to command the “fingers” motor, I had two options: a) use a flexible cable; b) use a Slip Ring to transmit the four signals.

The first option although simpler had a major drawback: on startup the wrist would have to be manually set in a known position otherwise there would be no way to make sure the wrist would not be commanded to rotate past the point where the flexible cable would start to entangle around the axle.

I then started to look for suitable Pancake Slip Rings but prices were significantly higher than I was prepared to pay for a prototype. So I decided to design and build a slip ring from scratch.

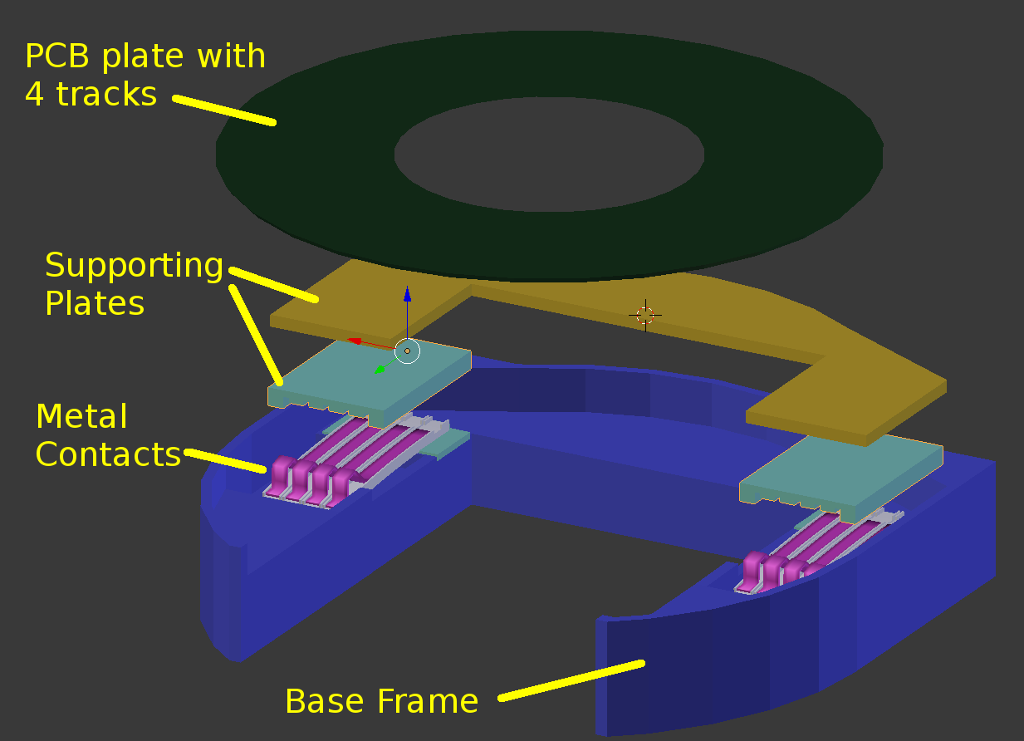

The design

The first step was to create a design that would fit the existing parts. The next figure shows the assembly components. The PCB plate is attached to the “hand” while everything else is part of the “wrist”. The signals are transmitted trough the metal contacts that are touching each of the four concentric tracks on the PCB plate:

The fabrication

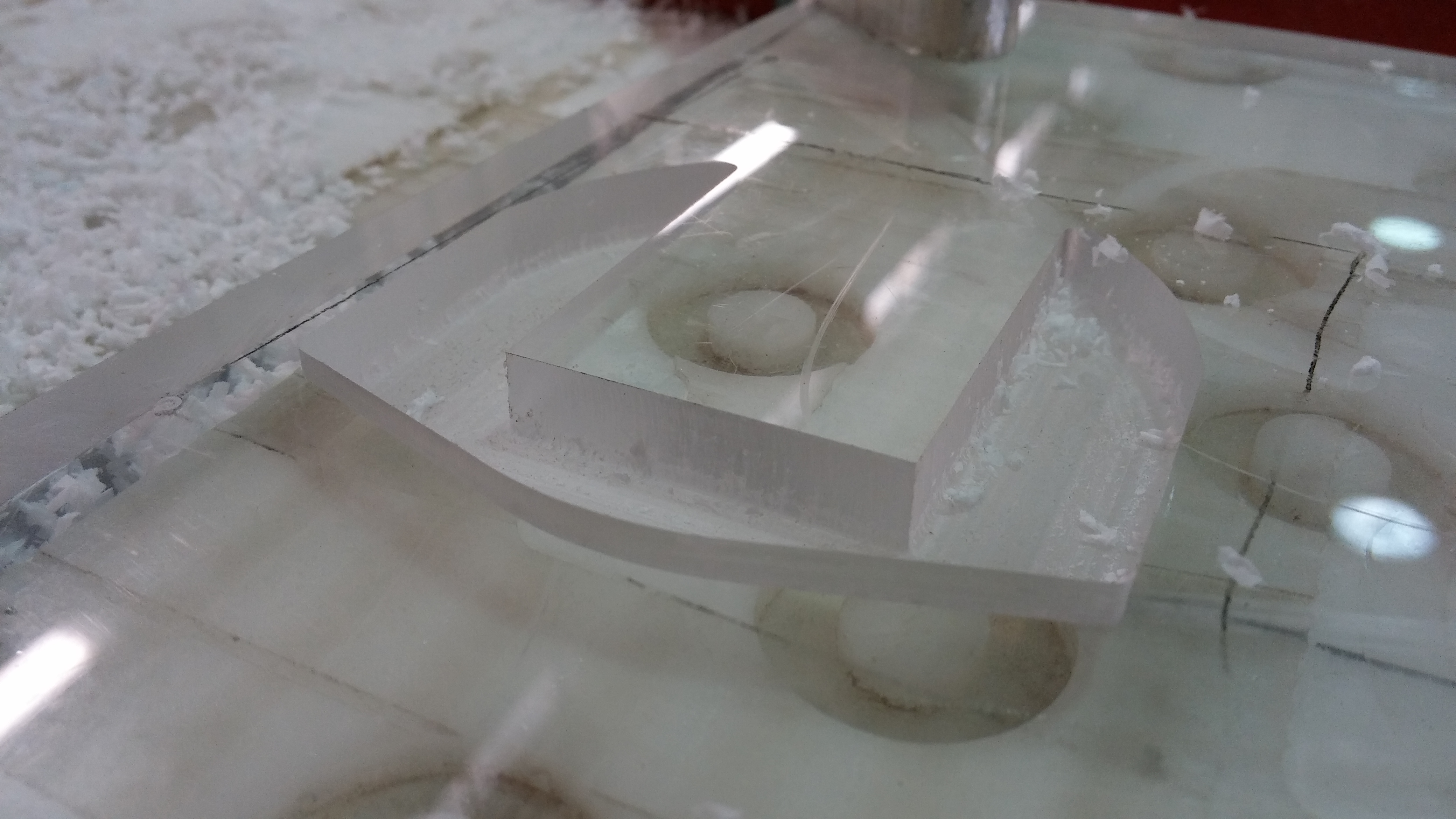

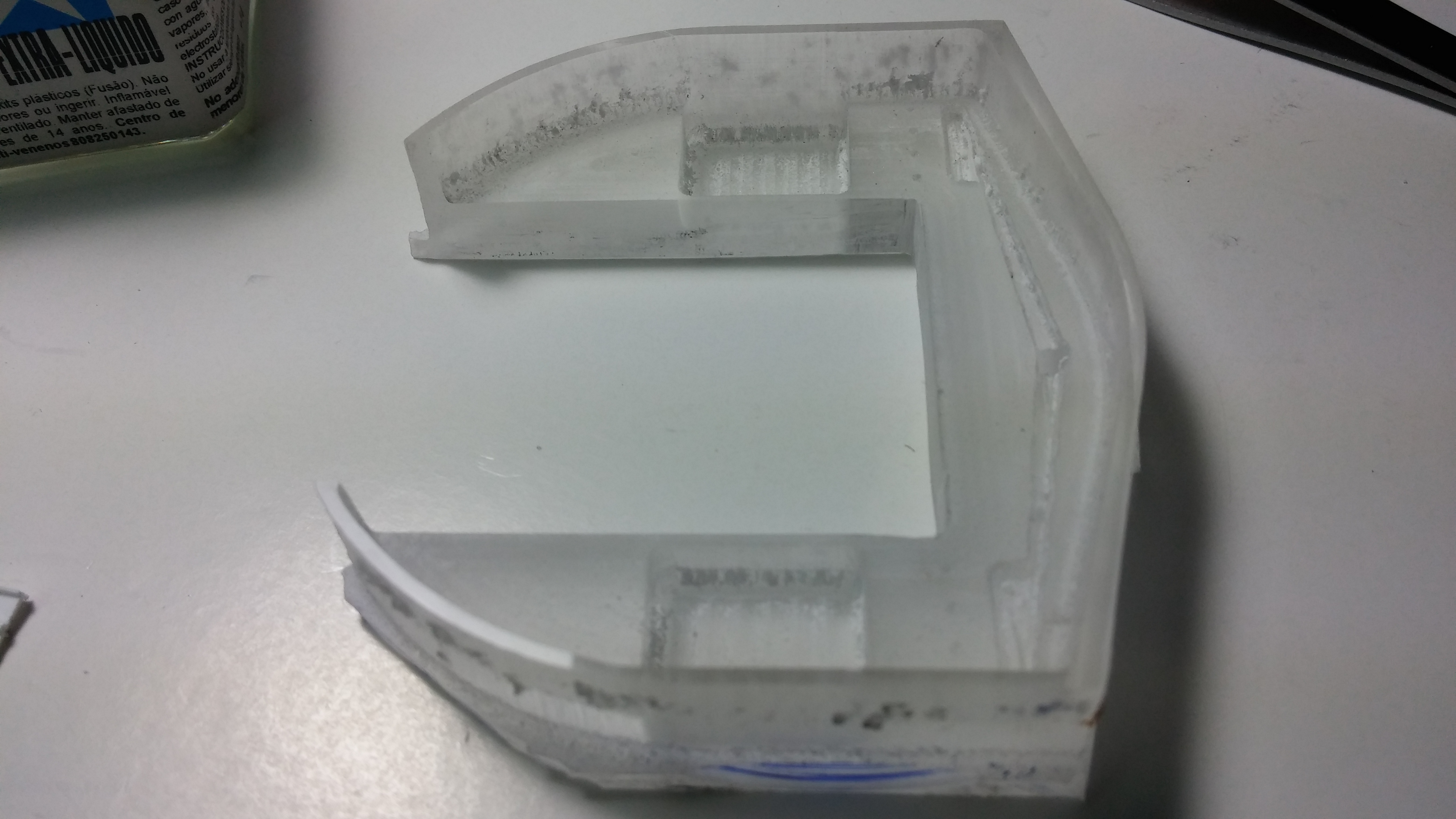

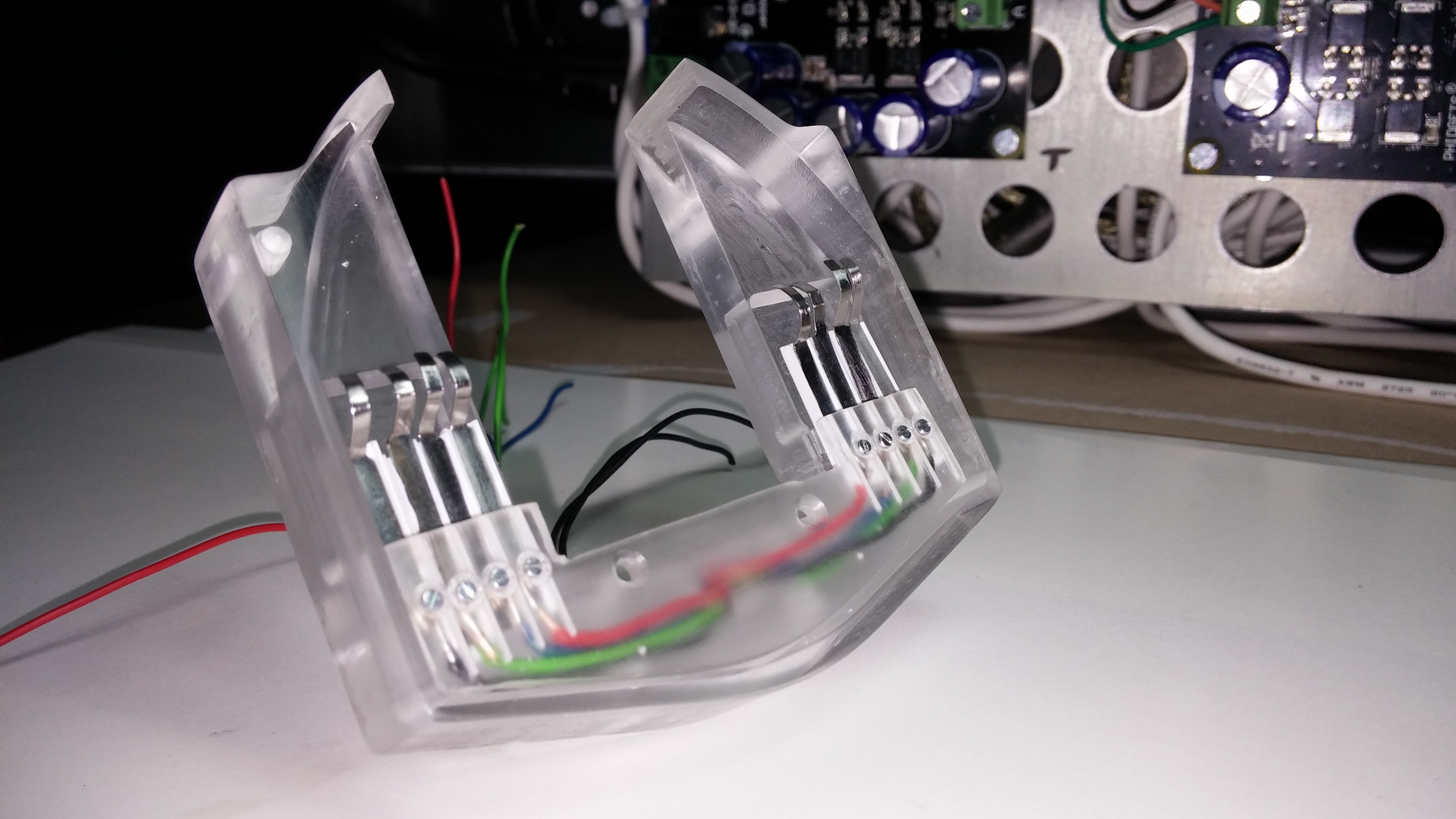

The base frame was fabricated by milling an acrylic plate.

The part before finishing:

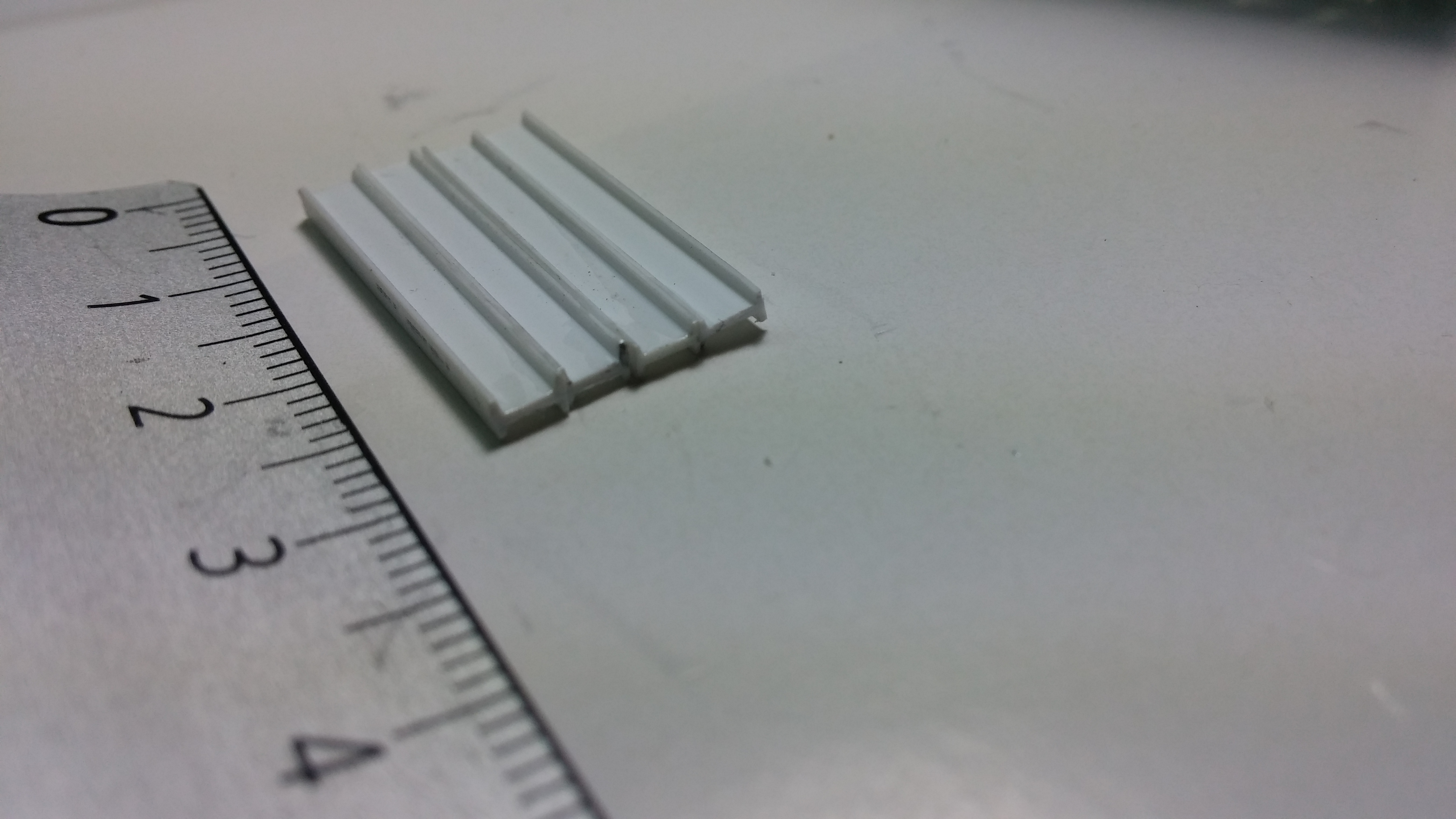

The contacts were cut from a sheet of metal salvaged from an old computer:

The metal contacts are held in place and separated from each other using small polystyrene profiles normally used for scale models.

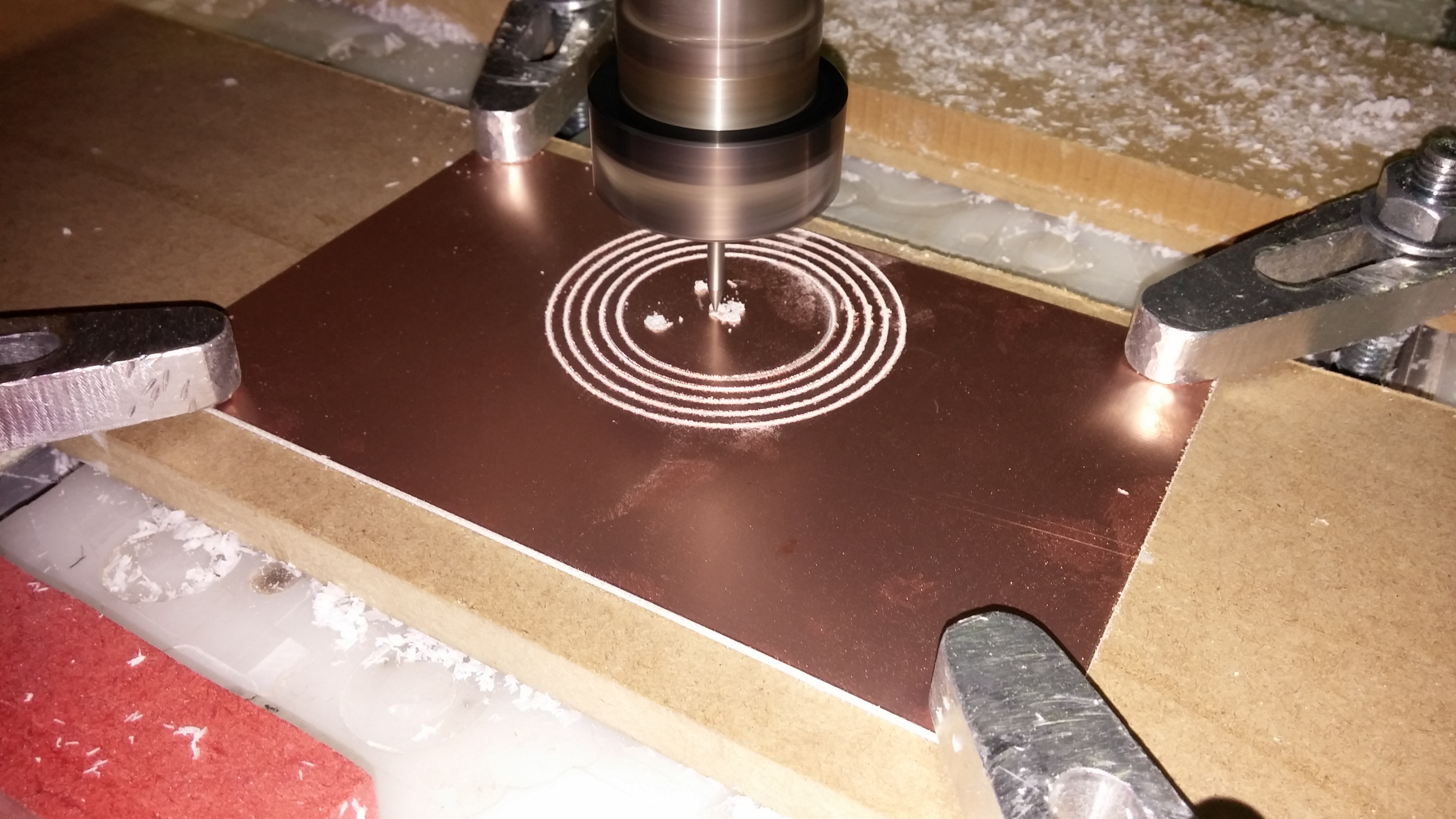

Finally the plate was milled from a standard piece of copper plated PCB:

The assembly with the wires already connected and ready to be set against the rotating plate:

The end result

This video shows the first tests using the custom made slip ring: